Our history

Ever since it was founded in Klagenfurt, our company has been firmly rooted in this region. Our founder Hans started to make his first bracelets on his own private premises in 1945, and his son Hermann has successfully expanded the business internationally from today’s location at number 5, Hirschstrasse.

Today, the company is managed by Robert Hirsch, the grandson of the company founder, together with his sons Nikolaus and Matthäus Hirsch.

As entrepreneurs, it has always been on the hearts of the Hirsch family to use Klagenfurt itself as a base for growing the company, creating sustainable jobs and being a trustworthy employer. This has been true right up to the present. Our corporate culture embodies longevity and differentiation but also self-awarness and willingness to change.

QUALITY AND INNOVATION

A bracelet is a product which is continually in direct skin contact and is worn for long periods of time. It is important that you can rely on its quality and are confident it will keep your watch safely on your wrist. The durability of a bracelet is significantly influenced by its use and by its user’s day-to-day habits.

So the product needs to be highly resilient.

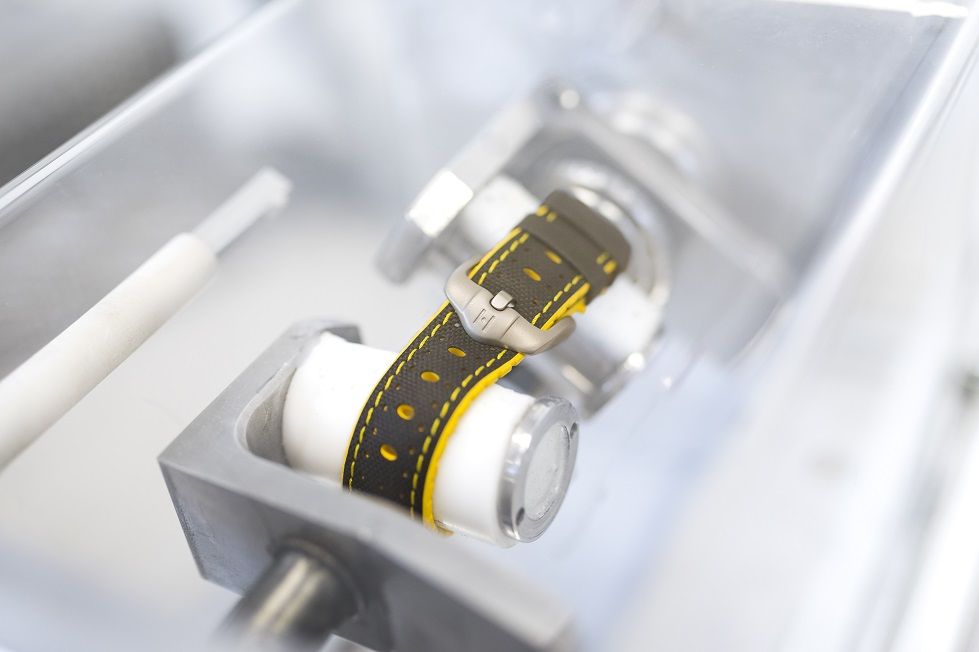

HIRSCH bracelets are therefore “sauna-tested”, to make sure they can withstand even extreme combinations of heat, moisture and sweat. The same goes for contact with water. HIRSCH bracelets are therefore generally water-resistant and dry more quickly than conventional watch straps – for example, when you wash your hands or have any other contact with water.

PRODUCTION PROCESSES

The production of a HIRSCH bracelet is highly sophisticated, and much of it is still done manually. A HIRSCH bracelet consists of three components:

- the upper leather (the side that faces you)

- the padding (inside the bracelet) and

- the lining (which is in direct contact with the skin)

To combine these three parts seamlessly and permanently, we use the so-called Rembordé technique, which was invented by the founder of the company, Hans Hirsch, and subsequently patented in 1955. This invention set a standard in the watch strap industry that continues to be recognised today.

This production method has a range of benefits:

Enclosed edges and an invisible transition between the upper leather and the lining as well as optimum protection against the intrusion of numerous substances, such as water, sweat, perfume, suncream and solvents, to which the bracelet is exposed on a daily basis.

Payment & Delivery

Payment & Delivery